idverde nominated for Pro Landscaper Business Awards 2025

We are delighted to share that idverde has been nominated for one of the Pro Landscaper Business Awards 2025!

Grounds Maintenance, Landscape Creation, Arboriculture, Sports Surfacing, Parks management, IOS Managing Safely Training, Ecology & Biodiversity, Grass cutting, Horticulture, Street Cleaning, Soft Landscaping, Hard Landscaping

idverde provides a wide range of green services, including grounds maintenance, landscape creation, and advice services, to both private and public sectors across the UK.

We are delighted to share that idverde has been nominated for one of the Pro Landscaper Business Awards 2025!

Pupils from Parkland Junior, Parkland Infant, Heron Park Academy, Willingdon and Polegate schools presented their carpet garden designs at the ‘Music In-Bloom’ finals at Eastbourne Town Hall on Thursday 6th March

idverde in partnership with the Royal Society for the Protection of Birds (RSPB) have partnered with HMP Humber to support both wildlife conservation and prisoner rehabilitation.

The inception of hedgelaying training in the Midlands dates back to 2022, following a highly enjoyable two-day training course attended by Ross Bray, RSPB/idverde Community and Biodiversity Adviser, with the Midlands Hedgelaying Group.

A new chapter has begun for Doagh as the Environmental Improvement Scheme to regenerate Doagh Corner and Anderson Park has been completed and the community space officially opened at a ribbon cutting ceremony recently.

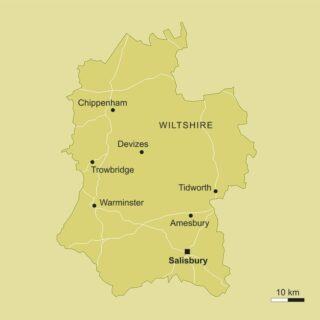

Wiltshire Council is joining forces with its contractor idverde to sponsor CPRE Wiltshire’s Best Kept Village competition for 2025.

idverde is delighted to have attended the prestigious BALI National Landscape Awards, an event that celebrates the outstanding achievements of the landscaping industry across the UK.

Storm Darragh recently swept across the UK, bringing fierce winds and heavy rainfall that have caused significant disruption, particularly in the South West and other severely affected regions. The storm has resulted in numerous fallen trees, scattered debris, and hazardous conditions, impacting communities and public spaces alike.

This month marks a significant milestone as idverde and the Royal Society for the Protection of Birds (RSPB) celebrate seven years of a fruitful partnership dedicated to enhancing biodiversity and promoting conservation across the UK. Since its inception, this collaboration has seen numerous impactful projects and initiatives, each contributing to the preservation and enrichment of natural habitats.

Grounds maintenance contractor, idverde, has been working in partnership with Loughborough in Bloom and Charnwood Borough Council to create a poppy installation in Queen’s Park in the lead-up to Remembrance Sunday.